1. DIY Powder Coating Machine Components and Structure

A DIY Powder Coating Machine typically includes a spray gun, powder container, grounding system, curing oven, and airflow control. The spray gun applies an electrostatic charge to powder particles, ensuring adhesion to grounded metal surfaces. A basic curing oven can be built using a modified kitchen oven or heat-resistant enclosure. Compact designs prioritize affordability and simplicity for home use.

2. Applications of DIY Powder Coating Machines

DIY Powder Coating Machines are ideal for small projects like automotive parts (wheels, brackets), bicycle frames, tools, and home decor. They provide durable, rust-resistant finishes for metals, making them popular among hobbyists and small workshops.

3. Cost of DIY Powder Coating Machine Setup

Building a DIY Powder Coating Machine costs 200–800. A basic spray gun kit starts at 50,whileamodifiedovenadds100–300.High−endDIYsetupswithprofessional−gradegunsandrecoverysystemsmayreach1,500. This is 80% cheaper than industrial systems.

4. How to Use a DIY Powder Coating Machine Safely

Clean surfaces thoroughly via sanding or degreasing. Ground the workpiece to ensure electrostatic adhesion. Apply powder in thin, even layers using a 6–10-inch spray distance. Cure parts at 350–400°F for 10–20 minutes. Always wear an N95 respirator and work in a well-ventilated area.

5. Choosing Parts for Your DIY Powder Coating Machine

Select a spray gun with adjustable voltage (30–70 kV) for versatility. Use a heat-resistant oven with precise temperature control. Opt for non-conductive powder containers to prevent static discharge. Prioritize lightweight, portable designs for easy storage.

6. Safety Tips for DIY Powder Coating Machines

Avoid flammable materials near the curing oven. Ground all components to prevent electric shocks. Use explosion-proof lighting in enclosed spaces. Store powders in airtight containers away from moisture. Never bypass safety switches on modified ovens.

7. Pros and Cons of DIY Powder Coating Machines

DIY systems save costs (70% vs. commercial units) and allow customization. However, they lack advanced recovery systems, leading to higher powder waste (15–20%). Limited automation makes them unsuitable for large batches but perfect for small-scale projects.

8. DIY Powder Coating Machine FAQs

Q: Can a DIY powder coating machine handle automotive parts?

A: Yes—proper grounding and curing ensure durable finishes on car components.

Q: What powders work best for DIY setups?

A: Polyester and epoxy powders are ideal for DIY powder coating machines due to low curing temps.

Q: How to reduce powder waste in DIY systems?

A: Use a cardboard spray booth to collect excess powder for reuse.

Q: Are DIY powder coating machines safe for indoor use?

A: Only with strong ventilation and a dedicated workspace to avoid dust buildup.

Q: Can I coat plastic with a DIY powder coating machine?

A: Yes—apply conductive primers first to enable electrostatic adhesion.

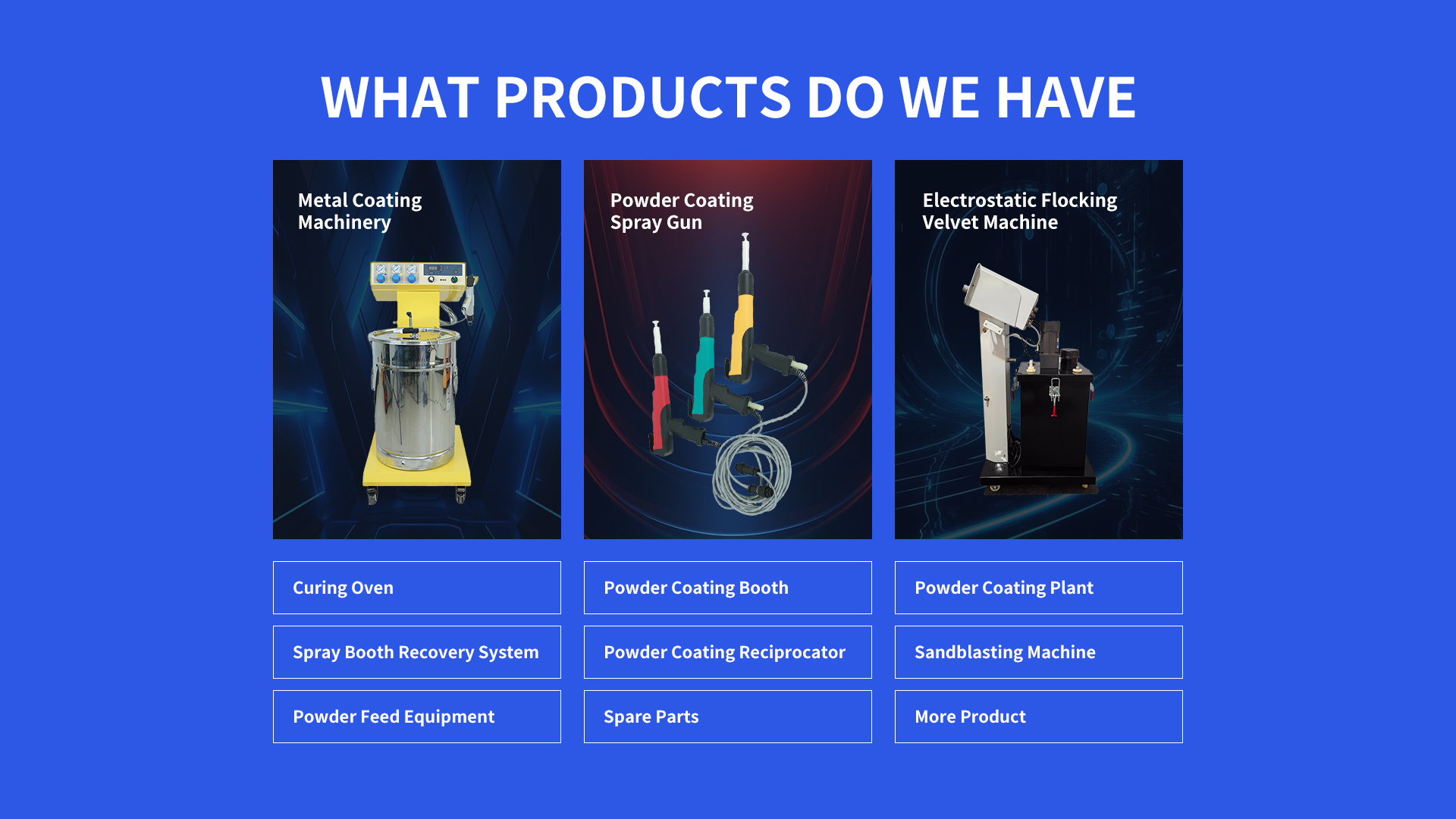

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com